DGT extraction and metal analysis by IFREMER

The DGT technique is used to extract and concentrate metal cations in situ. Their use has shown that this approach is applicable for many metallic elements (Ag, Al, Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb, Zn).

|

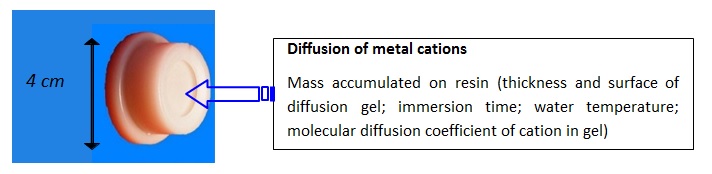

Photo: DGT resine recovery – april 2018 |

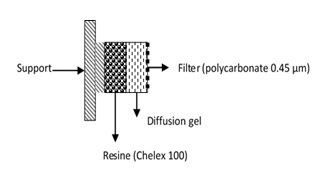

DGT are very simple devices to implement. They irreversibly accumulate (on a Chelex 100 resin) the most "labile" dissolved metal cations (hydrated ions, mineral complexes, small organic complexes) depending on their concentration in the medium and the immersion time. The device consists of a plastic support, on which are arranged successively a phase for which the metal cations have a very strong affinity (Chelex 100 resin), a diffusion hydrogel of known thickness and a protective polycarbonate filter (Fig. 1&2). The metal cations migrate through the diffusion gel and settle irreversibly on the resin. It is the diffusion, controlled by the physical properties of the gel, temperature and metal concentration in the medium to be sampled, that determines the accumulation kinetics on the resin. |

Figure 1: Photo of a DGT and operating principle

After recovery, the resin from each DGT is removed and eluted with nitric acid (1M). The eluate is analyzed by ICP-MS to determine the mass (M) of the various metallic elements accumulated in the resin.

Following the wet sampling campaign, most Monitool partners sent their DGT to Ifremer in April 2018. More than 150 DGTs were processed a few days after receipt (photo), then eluates were sent for ICP-MS analysis.

Figure 2: Cross-section view of a DGT (the proportions are not respected)